charpy impact test astm standard|charpy impact cheat sheet : private label The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod. For the test, a notched metal specimen is broken in half using a pendulum hammer. WEBOK Google. Sizzy. The browser for designers and developers. Absolute game-changer for working on responsive design.

{plog:ftitle_list}

6M Followers, 269 Following, 225 Posts - See Instagram photos and videos from Mariana Matarazzo (@marimatarazzoofc)

1.1 This test method is used to determine the resistance of plastics to breakage by flexural shock as indicated by the energy extracted from standardized (see Note 1) pendulum-type hammers, mounted in standardized machines, in breaking standard specimens with one .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod. For the test, a notched metal specimen is broken in half using a pendulum hammer.

CHARPY IMPACT TEST ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy .

Standards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy required to fracture a v-notched specimen. This energy .The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event).Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

Charpy impact tests are an effective way to observe how materials respond to various levels of impact at different temperatures. Manufacturers across numerous industries rely on Charpy impact tests to determine if their .

The standard test method for the Charpy impact resistance of FRP composites can be found in ASTM D6110 [51] and EN ISO 179 [52]. This test method can be performed in a fully .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

Identify apparatus and related components used for notched-bar impact testing of metallic materials. Recognize test specimen requirements for both Charpy and Izod specimens. Recall test procedures, including Charpy and Izod test procedures. Recall information obtainable from impact tests. Identify reporting requirements for ASTM E23.Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . The standard test for ASTM D256 requires specimens to be made with a milled notch. This is technically an equivalent standard to ISO 180 – Determination of Izod Impact . The single-blow Charpy impact test for gray and white irons shall be carried out in a pendulum-type impact machine. The test specimens shall have a plain cylindrical form, machined or ground to a smooth finish and shall conform to the specified values of diameter, length, and span. The standard notch Charpy bar impact test specimen shall be .

charpy v notch sample size

Compatible with the full range of CEAST impact testing systems, including pendulum type machines (CEAST 9000 Series) and drop towers (CEAST 9300 Series), it’s the key for instrumented impact testing. The DAS 64K also enables the data collection from instrumented tups or hammers on older models and non-CEAST impact machines.

charpy impact test standard pdf

Significance and Use 5.1 Brown and Lu4,5 show the Charpy impact energy is related to the ultimate critical temperature of the rapid crack propagation [RCP] behavior as measured by the ISO 13477, S-4 test.6 5.2 The test method may be used to determine theThe Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose . translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum • Thermometer • Water • Dry ice • Hot plate • Oven .The standards ISO 179-1 (non-instrumented impact strength test) and ISO 179-2 (instrumented impact strength test) describe the Charpy impact test for determination of the impact characteristics (impact strength and notched impact strength) of plastics.Impact tests to Charpy are also described in the ASTM D6110 standard. Impact tests according to the Charpy .

The excess energy pendulum impact test indicates the energy to break standard test specimens of specified size under stipulated parameters of specimen mounting, notching and pendulum velocity-at-impact. Testing Standards for ASTM and ISO. ASTM D256 – Standard Test Method for Determining the IZOD Pendulum Impact Resistance of Plastics

Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. . Table 1 of Classification D4000 lists the ASTM materials standards that currently exist. If there is no material specification, then the . The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C.These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers),

ClassiÞcation D4000 lists the ASTM materials standards that currently exist. If there is no material speciÞcation, then the requirements of this test method apply. 5.2 The pendulum impact test indicates the energy to break standard test specimens of speciÞed size under stipulated conditions of specimen mounting, notching (stress

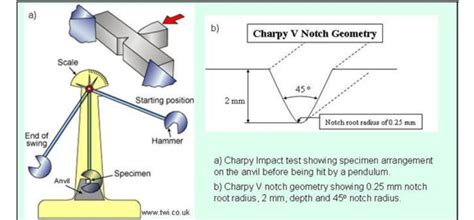

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . The standard Charpy-V notch specimen is 55mm long, 10mm square and has a 2mm deep notch with a tip radius of 0.25mm machined on one face .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significantASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum.

Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM standard E23 1, requiring a 55x10x10 mm beam with a 45°, 2 mm deep notch cut into the midpoint of the 55 mm side (Figure 2-1 1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide .

maven package test resources

Significance and Use 5.1 Brown and Lu4,5 show the Charpy impact energy is related to the ultimate critical temperature of the rapid crack propagation [RCP] behavior as measured by the ISO 13477, S-4 test.6 5.2 The test method may be used to determine the

maven package test jar

Classification D4000 lists the ASTM materials standards that currently exist. If there is no material specification, then the requirements of this test method apply. 5.2 The pendulum impact test indicates the energy to break standard test specimens of specified size under stipulated conditions of specimen mounting, notching (stress astm charpy impact test standard. According to ASTM A370,the standard specimen size for Charpy impact testing is 10 mm × 10mm × 55mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, 10 mm × 3.3 mm × 55 mm, 10 mm × 2.5 mm × 55 mm. Details of specimens as per ASTM A370 (Standard .

Different materials testing standards, such as ASTM E23, ASTM A370, and ASTM D256 govern the exact testing procedure and test specimen requirements for each type of impact test, and for different material groups (e.g., metals vs. plastics). . is used to determine Charpy impact strength. The standard test specimen is described in ASTM E23. It . The standard Charpy impact test specimen, as depicted in the procedure section, has dimensions of 55 mm × 10 mm × 10 mm, with a machined notch along one of the larger dimensions. . What Is the Difference Between the Charpy Impact Test and the IZOD Impact Strength Test? According to ASTM E23, the primary distinction between Charpy and Izod .

ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum. A typical Charpy test requires the notched metal specimen to rest on supports at each end (in a horizontal . Scope1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see AThe standard test procedure, ASTM D6110, is designed to ascertain the Charpy impact strength of specimens made of plastic material. The American Society for Testing and Materials (ASTM) is in charge of its creation. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests.Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity.

charpy impact test specimen size

Sung Won-Je Retired: 1 Medusa: Min Cheol An Retired: 1 Jesse: Jesse Eckley Free Agent: 1 Gheez: Lucas Nero Retired: 1 Nomfu: Aliff Amir Retired: 1 Pancake Retired: .

charpy impact test astm standard|charpy impact cheat sheet